CORE TECHNOLOGY AND EXPERTISE

North Side provides innovative solutions for well and reservoir performance evaluation through “tailored to clients’ needs” cased hole wireline technologies and downhole tools.

STREAM (FIND, TFT, T-FLOW), FLOWJET, MBTT, STT technologies, and cased hole logging tools to unlock the well potential or resolve integrity challenges.

Spinnerless Technologies for Reliable Evaluation, Analysis, and Modeling of well-reservoir flow

CORE TECHNOLOGY AND EXPERTISE

North Side provides innovative solutions for well and reservoir performance evaluation through “tailored to clients’ needs” cased hole wireline technologies and downhole tools.

STREAM (FIND, TFT, T-FLOW), FLOWJET®, MBTT, STT technologies, and cased hole logging tools to unlock the well potential or resolve integrity challenges.

High Resolution Segmented Thickness Tool

Wellbore flow profile in tough well and fluid conditions

CORE TECHNOLOGY AND EXPERTISE

North Side provides innovative solutions for well and reservoir performance evaluation through “tailored to clients’ needs” cased hole wireline technologies and downhole tools.

STREAM (FIND, TFT, T-FLOW), FLOWJET, MBTT, STT technologies, and cased hole logging tools to unlock the well potential or resolve integrity challenges.

Spinnerless Technologies for Reliable Evaluation, Analysis, and Modeling of well-reservoir flow

Permanent Downhole Production Monitoring System – Realtime production rate, water cut, pressure, and temperature data acquisition

CORE TECHNOLOGY AND EXPERTISE

North Side provides innovative solutions for well and reservoir performance evaluation through “tailored to clients’ needs” cased hole wireline technologies and downhole tools.

STREAM (FIND, TFT, T-FLOW), FLOWJET, MBTT technologies, and cased hole logging tools to unlock the well potential or resolve integrity challenges.

FIND

FLOW IDENTIFYING NOISE DETECTOR

Flow Identifying Noise Detector (FIND) is a complex technology solution comprised of the high-fidelity multi-sensor split channels spectral noise logging tool with the most advanced algorithms in data processing and analysis software. FIND is developed to assess well integrity and provide detailed profiles of well-reservoir flow.

- Response from active leak interval at various frequencies and amplitude against well completion

- Processes behind casing/liner

- Reservoir performance evaluation

T-FLOW

HIGH RESOLUTION TEMPERATURE MODELING

T-FLOW is an advanced numerical temperature simulation technology enabling comprehensive evaluation of reservoir flow profile behind the casing and open-hole wells. The technology is based on high-resolution temperature data acquisition and subsequent processing in in-house software.

Quantitative reservoir performance evaluation

Through-casing technology

100% data acquisition assurance

TFT

THERMAL FLOW TECHNOLOGY

Thermal Flow Technology (TFT) is an advanced solution for the accurate assessment of wellbore flow profile. This comprehensive system combines a high-sensitivity and wide-range flow logging tool with cutting-edge data processing software. The Thermal Flow Technology (TFT) offers the unique advantage of determining fluid velocity without the need for spinners, even in challenging logging conditions typically encountered in horizontal oil producers and polymer injectors.

STREAM

SPINNERLESS TECHNOLOGIES FOR RELIABLE EVALUATION, ANALYSIS AND MODELING OF WELL-RESERVOIR FLOW

Spinnerless Technologies for Reliable Evaluation, Analysis and Modeling of well-reservoir flow (STREAM) is a powerful suite of tools and technologies that provide high-resolution and accurate logging capabilities. STREAM is an integration of FIND, TFT AND T-FLOW technologies, working in perfect harmony to unlock unparalleled insights into the processes occurring inside and beyond the wellbore.

-

FIND

-

T-FLOW

-

TFT

MBTT

MULTIBARRIER THICKNESS TECHNOLOGY

Multi Barrier Thickness Technology (MBTT), an EM-based solution for accurate evaluation of metal loss of the well tubulars, pipe-by-pipe, up to 4 barriers even with scale deposition. MBTT technology utilizes corrosion logging tools and specialized in-house software for processing and analysis of acquired data.

-

Slickline conveyed

-

4-barrier memory mode tool

-

Azimuthal distribution of EM sensors

-

Accurate depth control (GR)

-

T and P additional sensors in the tool

STT

SEGMENTED THICKNESS TOOL

Multi Barrier High Resolution Segmented Thickness Technology (STT), an EM-based solution (logging tool and data processing software) for accurate evaluation of metal loss of the well tubulars, pipe-by-pipe, up to 2 barriers in segmented mode by 8 oriented high-resolution sensors, and up to 4th barrier inclusive by 2 long sondes in circumferential-average mode.

- 8HR-STT+2MBTT mode of sensors

- Azimuthally oriented measurement of 2 first barriers and 3+4 barriers circumferential average

- FIND compatible in SRO and Memory mode

- T and P is optional

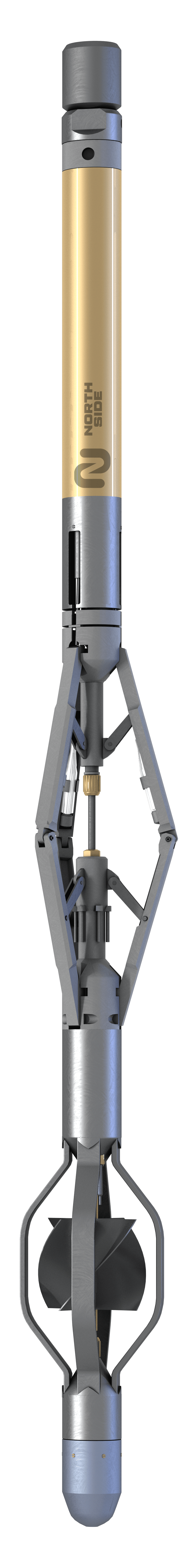

FLOWJET®

WELL-RESERVOIR PERFORMANCE EVALUATION IN ARTIFICIALLY LIFTED WELLS

FlowJet® is a cutting-edge technology engineered to efficiently lift the sub-hydrostatic oil wells during Production Logging Survey. This technology provides a seamless solution for PCP, BP, and ESP wells eliminating the need for a Y-tool or Dual string in their completion. FlowJet® simplifies the PLT survey, ensuring smooth operations and accurate data acquisition.

-

PLT in artificially lifted wells

-

No Y-tool required

-

Variable rate

-

Logging on an opportunity basis at failed AL replacement WO

-

Immediate result for workover continuation

-

Cost-effective solution

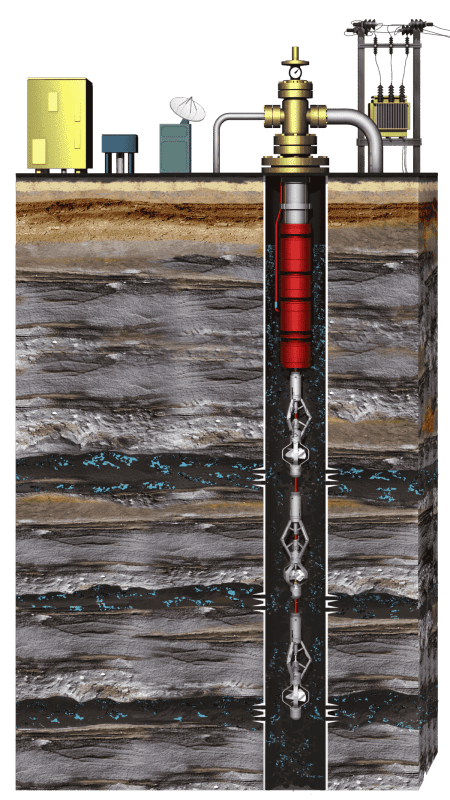

FLOW MASTER

PERMANENT DOWNHOLE PRODUCTION MONITORING SYSTEM

FLOW MASTER – Real-time production rate, water cut, pressure, and temperature data acquisition

Long-Term Zonal Production Monitoring

- Rod pump, ESP wells compatible

- Multizone production monitoring

- Integration to SCADA

DUAL MODE RELIABLE DATA ACQUISITION TOOLS

- Array or Single WHU sensor

- Quartz pressure sensor

- Flow-sensitive bi-directional full-bore spinner

- Built-in battery and memory for data backup

- Up to 6 tools suspended in a chain

CORE TECHNOLOGY AND EXPERTISE

North Side provides innovative solutions for well and reservoir performance evaluation through “tailored to clients’ needs” cased hole wireline technologies and downhole tools.

STREAM (FIND, TFT, T-FLOW), FLOWJET®, MBTT, STT technologies, and cased hole logging tools to unlock the well potential or resolve integrity challenges.

Well-reservoir performance evaluation in artificially lifted wells

Permanent Downhole Production Monitoring System

Core Technology and Expertise

Permanent Downhole Production Monitoring System

Well-reservoir performance evaluation in artificially lifted wells

FIND

Flow Identifying Noise Detector (FIND) is a complex technology solution comprised of the high-fidelity multi-sensor split channels spectral noise logging tool with the most advanced algorithms in data processing and analysis software. FIND is developed to assess well integrity and provide detailed profiles of well-reservoir flow.

- Response from active leak interval at various frequencies and amplitude against well completion

- Processes behind casing/liner

- Reservoir performance evaluation

Flow Identifying Noise Detector (FIND) is a complex technology solution comprised of the high-fidelity multi-sensor split channels spectral noise logging tool with the most advanced algorithms in data processing and analysis software. FIND is developed to assess well integrity and provide detailed profiles of well-reservoir flow.

- Response from active leak interval at various frequencies and amplitude against well completion

- Processes behind casing/liner

- Reservoir performance evaluation

FIND Technology & Case Studies

FIND Technology & Case Studies

T-FLOW

High Resolution Temperature Modeling

T-FLOW is an advanced numerical temperature simulation technology enabling comprehensive evaluation of reservoir flow profile behind the casing and open-hole wells. The technology is based on high-resolution temperature data acquisition and subsequent processing in in-house software.

Quantitative reservoir performance evaluation

Through-casing technology

100% data acquisition assurance

T-FLOW is an advanced numerical temperature simulation technology enabling comprehensive evaluation of reservoir flow profile behind the casing and open-hole wells. The technology is based on high-resolution temperature data acquisition and subsequent processing in in-house software.

Quantitative reservoir performance evaluation

Through-casing technology

100% data acquisition assurance

T-FLOW Case Studies

TFT

Thermal Flow Technology

Thermal Flow Technology (TFT) is an advanced solution for the accurate assessment of wellbore flow profile. This comprehensive system combines a high-sensitivity and wide-range flow logging tool with cutting-edge data processing software. The Thermal Flow Technology (TFT) offers the unique advantage of determining fluid velocity without the need for spinners, even in challenging logging conditions typically encountered in horizontal oil producers and polymer injectors.

TFT Case Studies

STREAM

SPINNERLESS TECHNOLOGIES FOR RELIABLE EVALUATION, ANALYSIS AND MODELING OF WELL-RESERVOIR FLOW

Spinnerless Technologies for Reliable Evaluation, Analysis and Modeling of well-reservoir flow (STREAM) is a powerful suite of tools and technologies that provide high-resolution and accurate logging capabilities. STREAM is an integration of FIND, TFT AND T-FLOW technologies, working in perfect harmony to unlock unparalleled insights into the processes occurring inside and beyond the wellbore.

FIND

T-FLOW

TFT

Spinnerless Technologies for Reliable Evaluation, Analysis and Modeling of well-reservoir flow (STREAM) is a powerful suite of tools and technologies that provide high-resolution and accurate logging capabilities. STREAM is an integration of FIND, TFT AND T-FLOW technologies, working in perfect harmony to unlock unparalleled insights into the processes occurring inside and beyond the wellbore.

FIND

T-FLOW

TFT

STREAM Case Studies

MBTT

MULTIBARRIER THICKNESS TECHNOLOGY

Multi Barrier Thickness Technology (MBTT), an EM-based solution for accurate evaluation of metal loss of the well tubulars, pipe-by-pipe, up to 4 barriers even with scale deposition. MBTT technology utilizes corrosion logging tools and specialized in-house software for processing and analysis of acquired data.

-

Slickline conveyed

-

4-barrier memory mode tool

-

Azimuthal distribution of EM sensors

-

Accurate depth control (GR)

-

T and P additional sensors in the tool

Multi Barrier Thickness Technology (MBTT), an EM-based solution for accurate evaluation of metal loss of the well tubulars, pipe-by-pipe, up to 4 barriers even with scale deposition. MBTT technology utilizes corrosion logging tools and specialized in-house software for processing and analysis of acquired data.

Slickline conveyed

4-barrier memory mode tool

Azimuthal distribution of EM sensors

Accurate depth control (GR)

T and P additional sensors in the tool

MBTT

STT

SEGMENTED THICKNESS TOOL

Multi Barrier High Resolution Segmented Thickness Technology (STT), an EM-based solution (logging tool and data processing software) for accurate evaluation of metal loss of the well tubulars, pipe-by-pipe, up to 2 barriers in segmented mode by 8 oriented high-resolution sensors, and up to 4th barrier inclusive by 2 long sondes in circumferential-average mode.

- 8HR-STT+2MBTT mode of sensors

- Azimuthally oriented measurement of 2 first barriers and 3+4 barriers circumferential average

- FIND compatible in SRO and Memory mode

- T and P is optional

STT

FLOWJET®

WELL-RESERVOIR PERFORMANCE EVALUATION IN ARTIFICIALLY LIFTED WELLS

FlowJet® is a cutting-edge technology engineered to efficiently lift the sub-hydrostatic oil wells during Production Logging Survey. This technology provides a seamless solution for PCP, BP, and ESP wells eliminating the need for a Y-tool or Dual string in their completion. FlowJet® simplifies the PLT survey, ensuring smooth operations and accurate data acquisition.

PLT in artificially lifted wells

No Y-tool required

Variable rate

Logging on an opportunity basis at failed AL replacement WO

Immediate result for workover continuation

Cost-effective solution

FlowJet© is a cutting-edge technology engineered to efficiently lift the sub-hydrostatic oil wells during Production Logging Survey. This technology provides a seamless solution for PCP, BP, and ESP wells eliminating the need for a Y-tool or Dual string in their completion. FlowJet simplifies the PLT survey, ensuring smooth operations and accurate data acquisition.

PLT in artificially lifted wells

No Y-tool required

Variable rate

Logging on an opportunity basis at failed AL replacement WO

Immediate result for workover continuation

Cost-effective solution

MPLT in Artificially Lifted Wells

Drill Stem Test with Flowjet

Drill Stem Test with FlowJet© is the best way to test multilayered formations zone by zone creating variable drawdown to the reservoir to evaluate its performance at different flow regimes.

MEFM tool helps to measure gross rate, water cut, pressure and temperature during production test downhole with unlimited test duration, perform PBUS.

- During production and testing MEFM tool records all stated above parameters to its internal memory at a sampling rate of 0.25 – 60 seconds.

- The well test insert with the MEFM tool can be retrieved from the hole using slickline, along with the assistance of a supplied fishing tool.

- There is no set time limit for the production, allowing it to continue without any restrictions on duration.

- PVT sampling can also be conducted during stationary well flow conditions.

- The collection of PVT samples enables obtaining clean and uncontaminated reservoir fluid samples from remote zones of the formation, devoid of any remnants of drilling mud. The PVT chamber, utilized for this purpose, consists of two 500cc containers equipped with a timer and pressure triggers.

Drill Stem Test with FlowJet

FLOW MASTER

PERMANENT DOWNHOLE PRODUCTION MONITORING SYSTEM

Flow Mater – Real-time production rate, water cut, pressure, and temperature data acquisition