DATA INTERPRETATION

DATA INTERPRETATION

WELL INTEGRITY DATA ANALYSIS

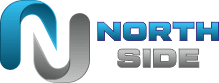

Analysis of Well Barrier Structural Integrity

For almost 10 years (a decade), we have specialized in the analysis of well integrity data, providing reliable data analytics solutions to clients worldwide. Our expertise lies in evaluating well integrity, which involves gaining a comprehensive understanding of the performance of barriers within your well. This encompasses assessing the structural integrity of tubing, casing, and liners, with the ultimate goal of mitigating risk, prolonging well life, and optimizing well management throughout their operational lifespan.

Our solutions for corrosion logging data analysis assist clients in:

- Effectively manage risk

- Extend the operational lifespan of their wells

- Detect defects at an early stage

- Minimize the cost of remedial actions

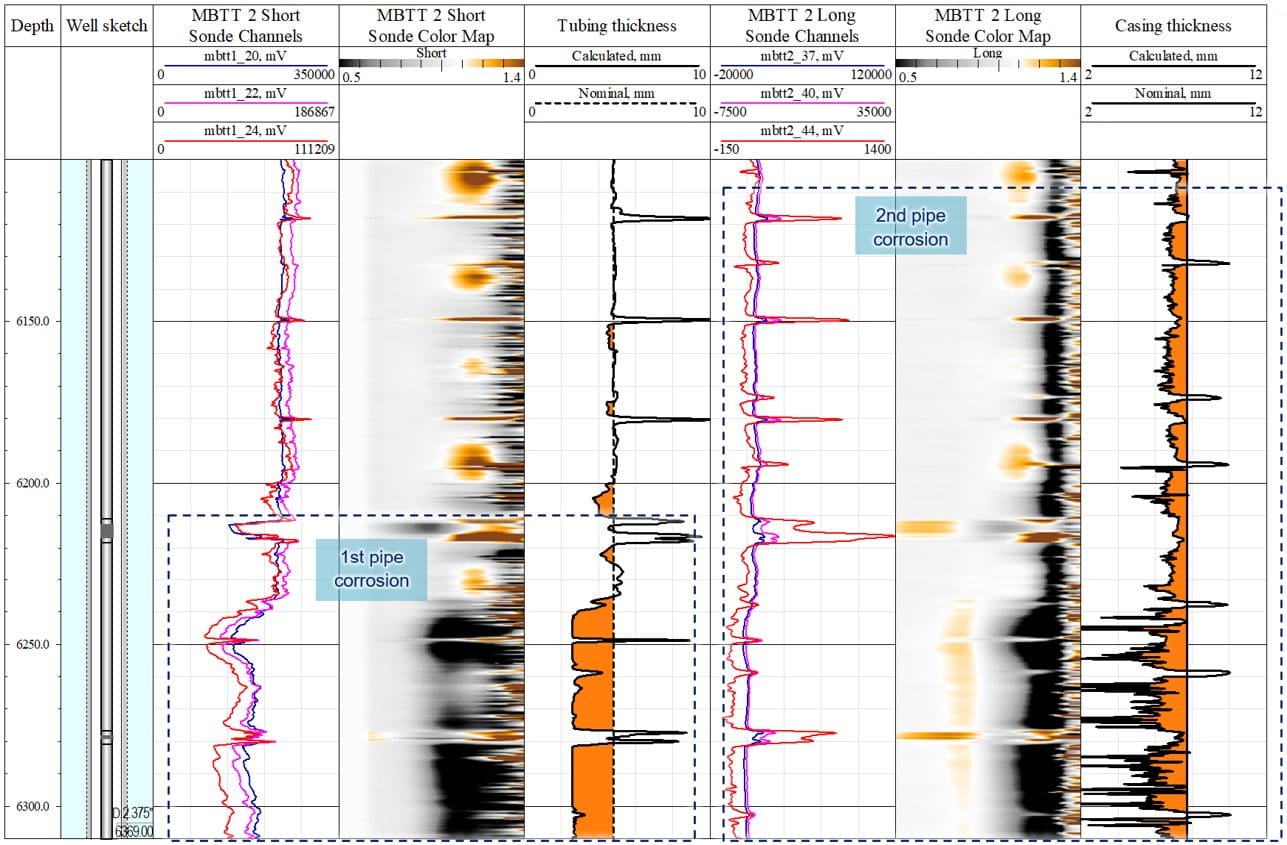

Analysis of Well Integrity in terms of leak or channeling detection and analysis

Utilizing our split channels spectral logging tool (FIND) in conjunction with high-resolution temperature logging (HRT) data, we can precisely identify the location of well barrier leaks. Additionally, we can capture processes occurring behind the casing, including issues such as channelings due to cement bond structural problems.

The split channels architecture of FIND enables the robust detection of low, mid, and high-frequency noise events associated with processes occurring inside the well or behind well barriers, providing a high level of confidence in the captured data.

Our solutions for leak detection data analysis assist clients in:

- Detect leaks in well barriers and / or behind them

- Extend the operational lifespan of their wells

- Plan exact the cost of remedial actions

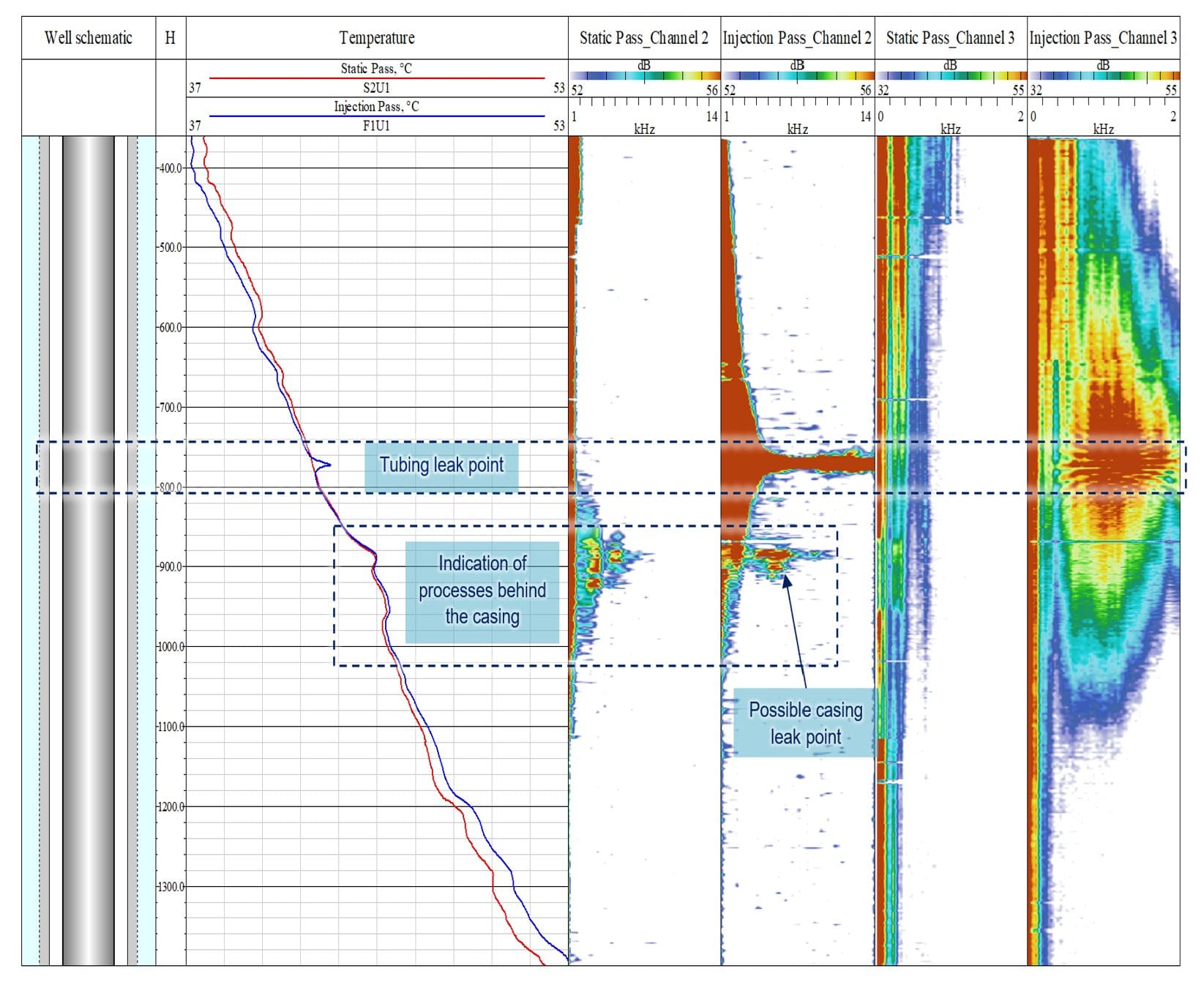

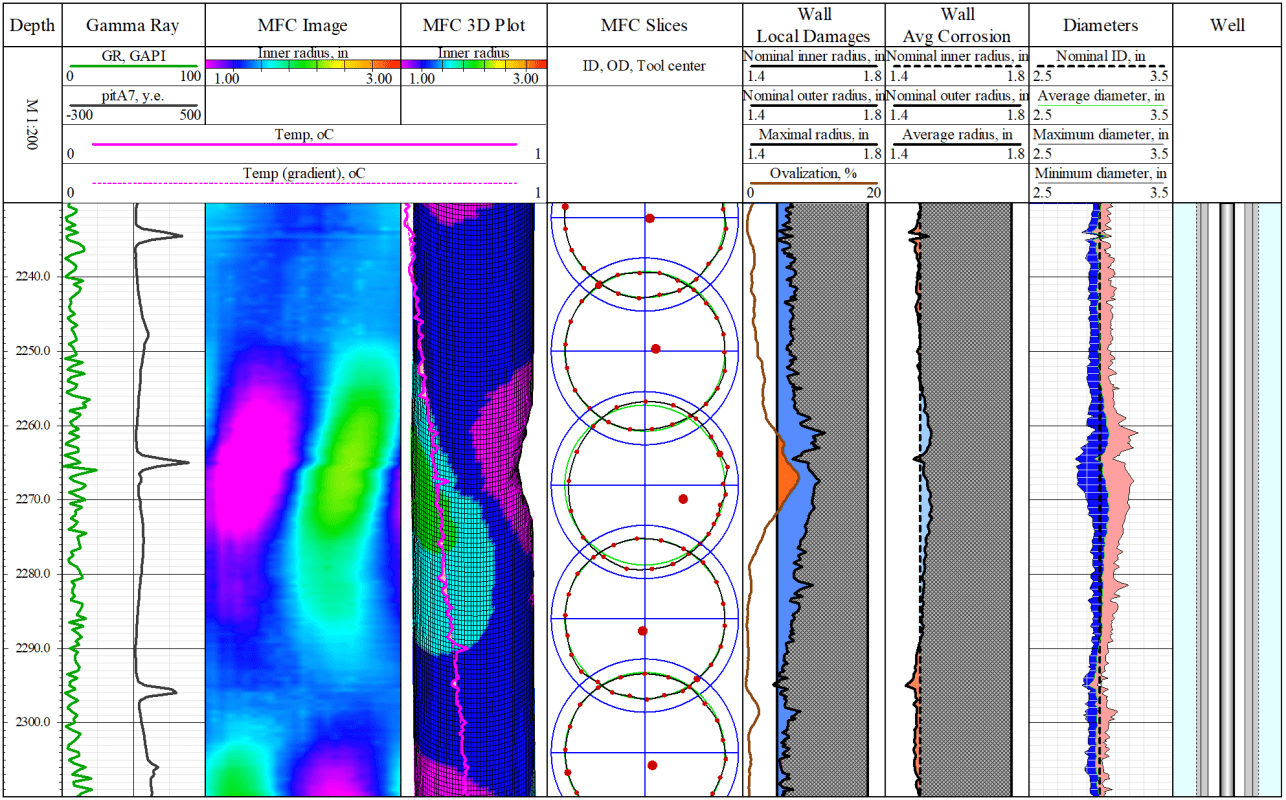

Multifinger Caliper Analysis

We have the capability to work with caliper datasets from any technology supplier. Our expertise lies in processing, analyzing, and interpreting multifinger caliper data, providing valuable insights into well accessibility concerns. This is accomplished by directly measuring smaller-than-expected internal diameters (IDs), and through the application of advanced data analytics methods, we can unveil the true 3D geometry of the tubulars.

Whether it’s assessing issues related to deposition, drilling wear, or optimizing the positioning of plugs and packers, we offer our clients in-depth analysis that enables the swift identification of integrity issues. This empowers them to make well-informed decisions regarding the most suitable remedial actions.

Our solutions for MCF data analysis assist clients in:

- Deeper understanding of extent of damage with 3D visualization

- Predict future casing/tubing failures

- Reduced workover decision time and minimal lost production

Acoustic Scanner Data Analysis

When utmost accuracy is essential for your ultrasonic data, whether for critical burst and pressure calculations or for facilitating time-lapse studies, we possess the expertise to deliver precise analysis, acquired by our set of acoustic tools or interpretation of third-party data.

We have the proficiency to evaluate ultrasonic-acquired data and offer our clients highly accurate measurements of internal diameter (ID) and thickness for both tubing and casing. This analysis reveals issues such as corrosion, mechanically induced damage, and deformations.

Our solutions for ASD data analysis assist clients in:

- Deeper understanding of extent of damage with 3D visualization

- Predict future casing/tubing failures

- Reduced workover decision time and minimize lost of production

- Detailed visualization of inner surface of well tubular

- Interior and exterior corrosion

- Pitting, Parting, Splits, Scale deposition, Paraffin build-up, Holes, Casing/tubing deformation, perforation zones

- Downhole item condition, e.g. nipples, side pocket mandrels

- Sliding sleeve position

- Fractures, vugs in open hole wells

DATA INTERPRETATION

WELL INTEGRITY DATA ANALYSIS

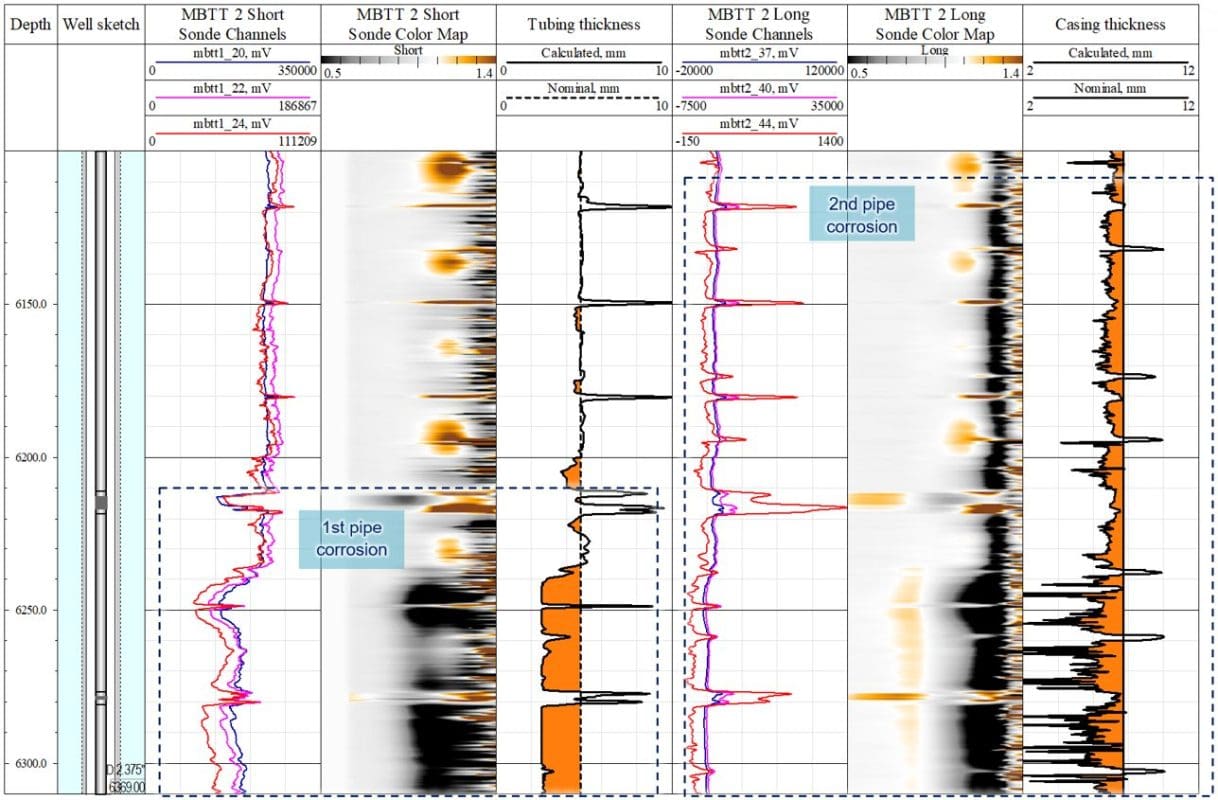

Multi Barrier Corrosion Logging

Analysis

Analysis of Well Barrier Structural Integrity

For almost 10 years (a decade), we have specialized in the analysis of well integrity data, providing reliable data analytics solutions to clients worldwide. Our expertise lies in evaluating well integrity, which involves gaining a comprehensive understanding of the performance of barriers within your well. This encompasses assessing the structural integrity of tubing, casing, and liners, with the ultimate goal of mitigating risk, prolonging well life, and optimizing well management throughout their operational lifespan.

Our solutions for corrosion logging data analysis assist clients in:

- Effectively manage risk

- Extend the operational lifespan of their wells

- Detect defects at an early stage

- Minimize the cost of remedial actions

Data Deliverables

- Calculated circumferential thickness of the well barriers from 1 up to 4

- Calculated 8 segmented (oriented) thickness of well barriers

- Quantitative metal loss of the well barriers including segmentation

- Detect defects of the well tubular

- Comprehensive report issuing

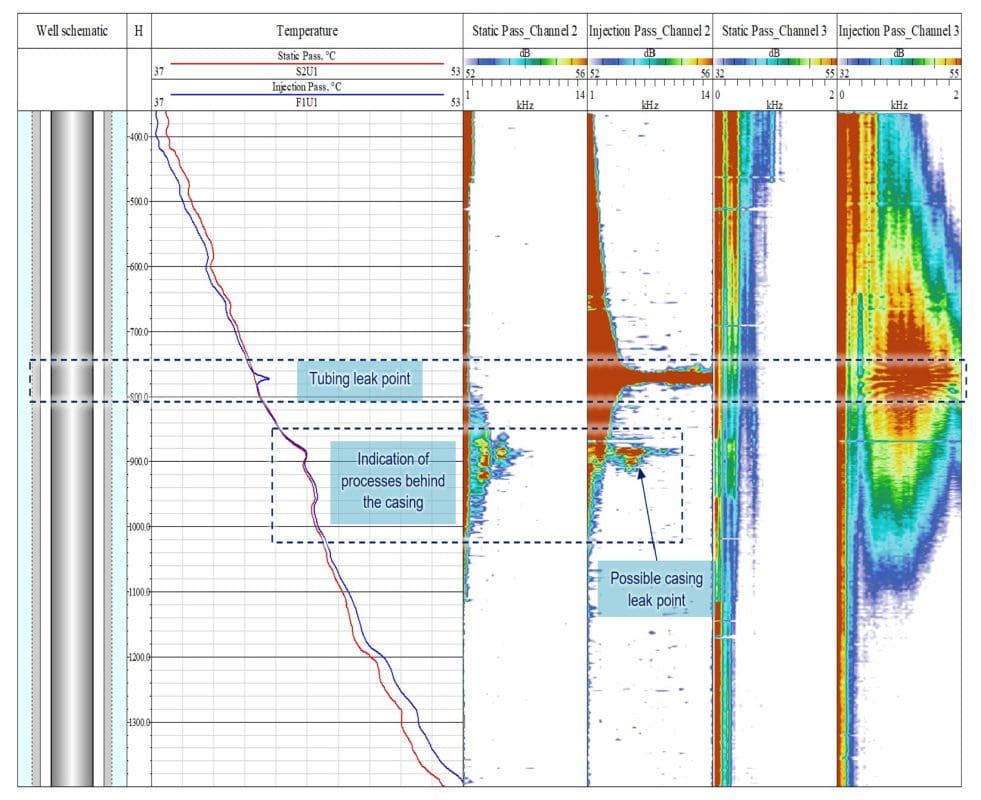

Leak Detection Logging

Analysis

Analysis of Well Integrity in terms of leak or channeling detection and analysis

Utilizing our split channels spectral logging tool (FIND) in conjunction with high-resolution temperature logging (HRT) data, we can precisely identify the location of well barrier leaks. Additionally, we can capture processes occurring behind the casing, including issues such as channelings due to cement bond structural problems.

The split channels architecture of FIND enables the robust detection of low, mid, and high-frequency noise events associated with processes occurring inside the well or behind well barriers, providing a high level of confidence in the captured data.

Our solutions for leak detection data analysis assist clients in:

- Detect leaks in well barriers and / or behind them

- Extend the operational lifespan of their wells

- Plan exact the cost of remedial actions

Data Deliverables

- Exact location of the leak point

- Location of channeling behind casing

- Appraisal of sealing performance of cement barriers

- Quantitative calculation of leak/channeling rate

Multifinger Caliper (MFC) Logging

Analysis

Multifinger Caliper Analysis

We have the capability to work with caliper datasets from any technology supplier. Our expertise lies in processing, analyzing, and interpreting multifinger caliper data, providing valuable insights into well accessibility concerns. This is accomplished by directly measuring smaller-than-expected internal diameters (IDs), and through the application of advanced data analytics methods, we can unveil the true 3D geometry of the tubulars.

Whether it’s assessing issues related to deposition, drilling wear, or optimizing the positioning of plugs and packers, we offer our clients in-depth analysis that enables the swift identification of integrity issues. This empowers them to make well-informed decisions regarding the most suitable remedial actions.

Our solutions for MCF data analysis assist clients in:

- Deeper understanding of extent of damage with 3D visualization

- Predict future casing/tubing failures

- Reduced workover decision time and minimal lost production

Data Deliverables

- Interior and exterior corrosion

- Pitting, Parting, Splits, Scale deposition, Paraffin build-up, Holes, Casing/tubing deformation

- Downhole item condition, e.g. nipples, side pocket mandrels

- Sliding sleeve position

Acoustic Scanner Logging

Analysis

Acoustic Scanner Data Analysis

When utmost accuracy is essential for your ultrasonic data, whether for critical burst and pressure calculations or for facilitating time-lapse studies, we possess the expertise to deliver precise analysis, acquired by our set of acoustic tools or interpretation of third-party data.

We have the proficiency to evaluate ultrasonic-acquired data and offer our clients highly accurate measurements of internal diameter (ID) and thickness for both tubing and casing. This analysis reveals issues such as corrosion, mechanically induced damage, and deformations.

Our solutions for ASD data analysis assist clients in:

- Deeper understanding of extent of damage with 3D visualization

- Predict future casing/tubing failures

- Reduced workover decision time and minimize lost of production

Data Deliverables

- Detailed visualization of inner surface of well tubular

- Interior and exterior corrosion

- Pitting, Parting, Splits, Scale deposition, Paraffin build-up, Holes, Casing/tubing deformation, perforation zones

- Downhole item condition, e.g. nipples, side pocket mandrels

- Sliding sleeve position

- Fractures, vugs in open hole wells

PRODUCTION LOGGING DATA ANALYSIS

Standard PLT Data Analysis

Analysis

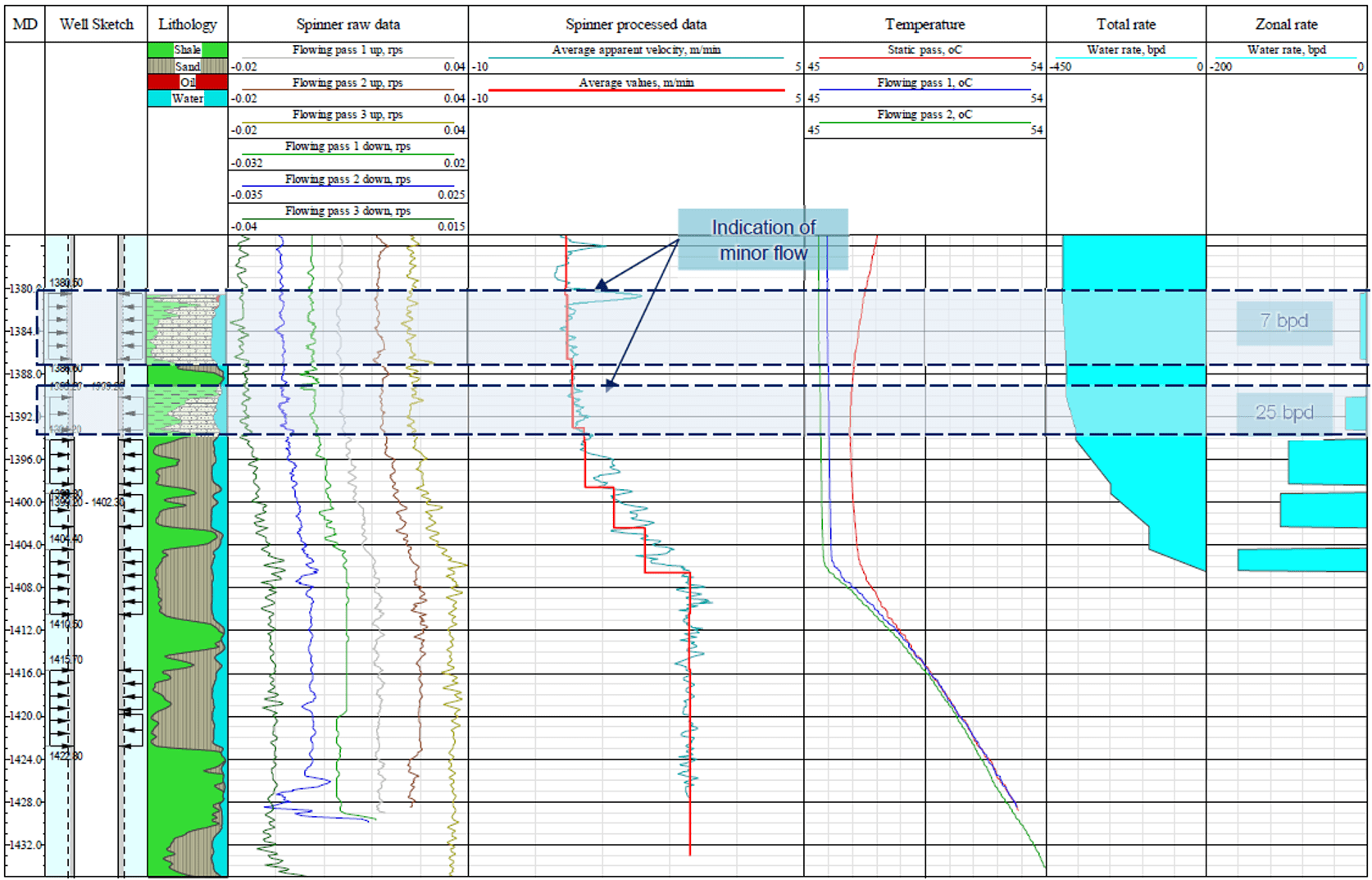

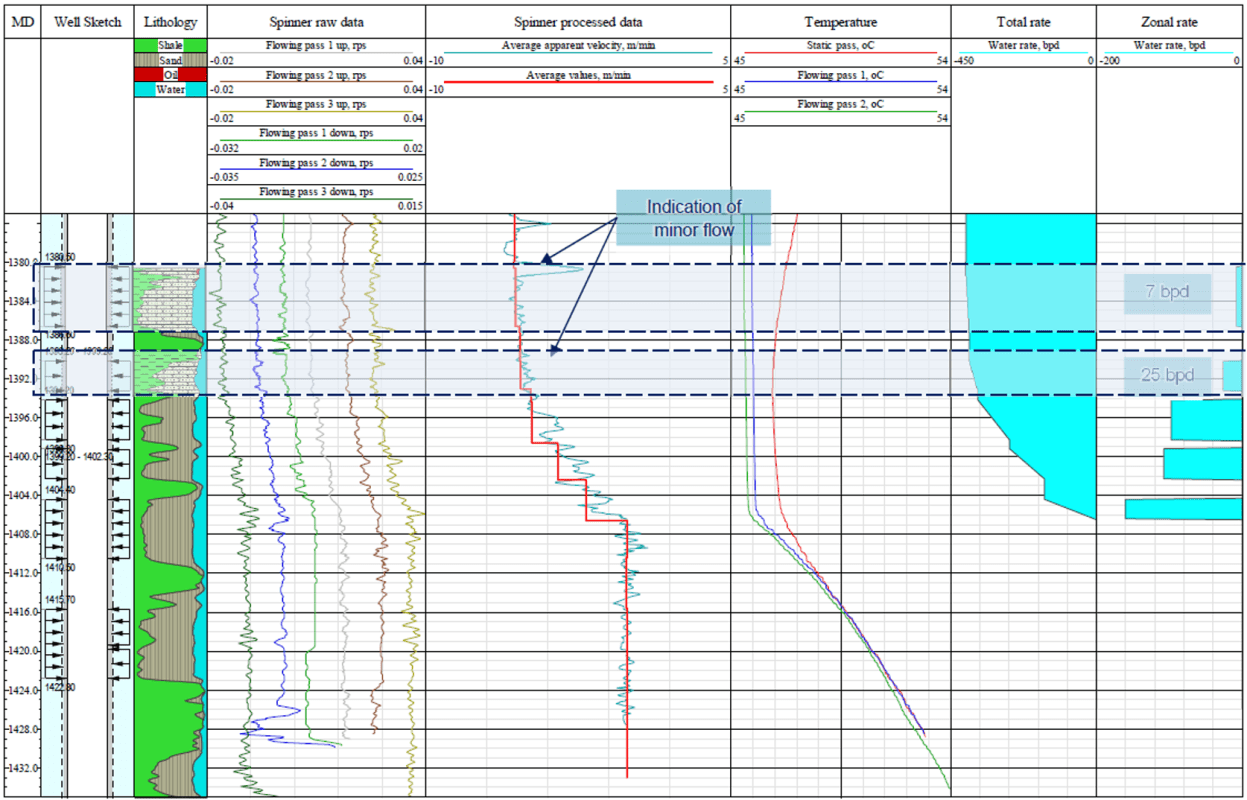

Wellbore Flow Profiling

Standard production logging tools are capable of providing a comprehensive well profile, whether it’s related to production or injection activities. In the past decade, North-Side has conducted extensive analysis on hundreds of wells across the globe. We’ve assisted numerous operators in boosting their production rates and have also aided numbers of service companies in delivering top-tier analysis to their clients.

Our solutions for Standard PLT data analysis assist clients in:

- Reservoir performance evaluation

- Identification of cross-flow in multizone perforated wells

- Localization of water source in high water cut wells for further WSO

- Build base-line understanding of well performance after commissioning

Data Deliverables

Data deliverables

- Detailed production/injection profiles

- Fluid parameters inside the wellbore

- Cross-flow intervals

Array PLT Logging

Analysis

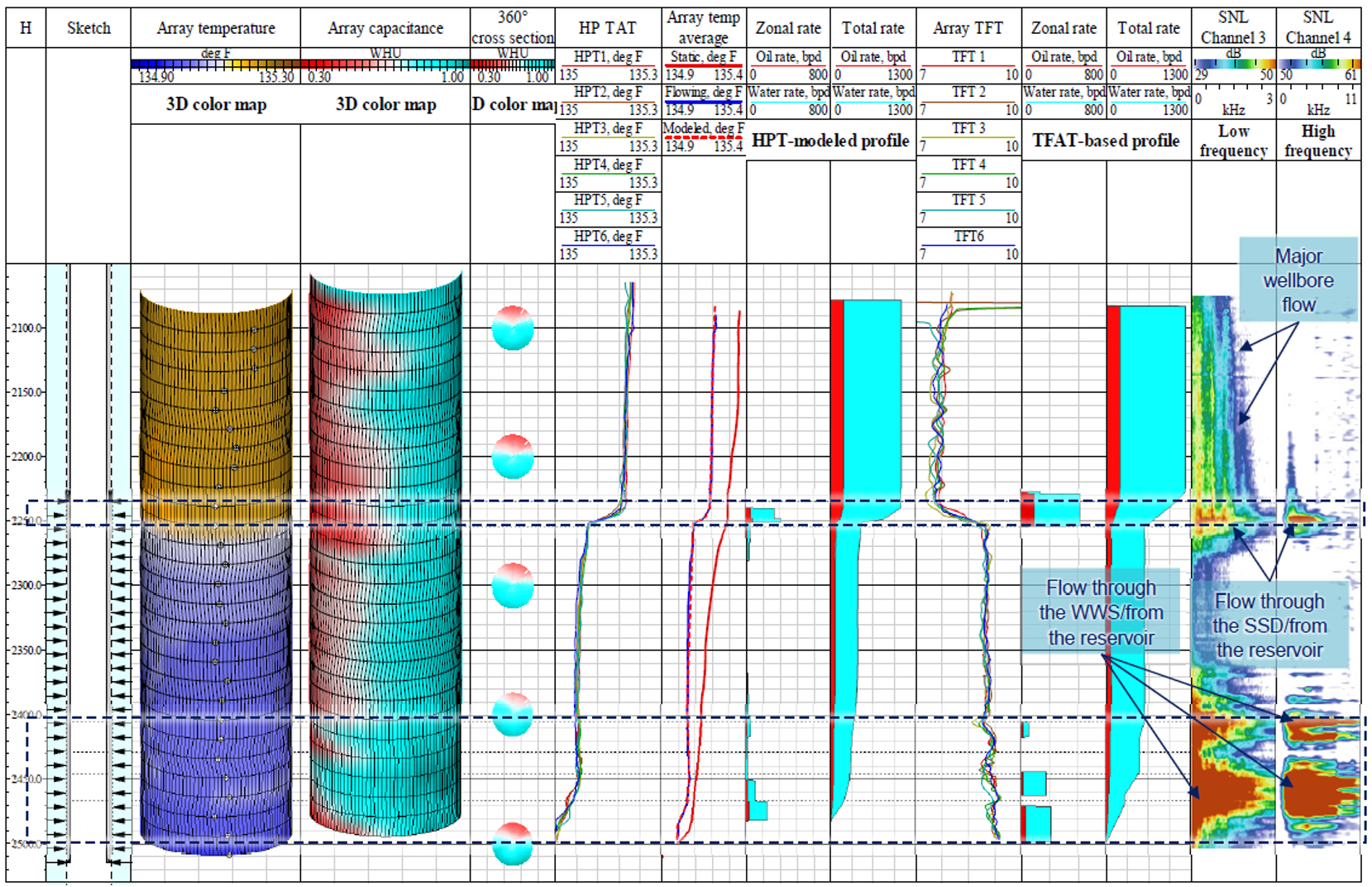

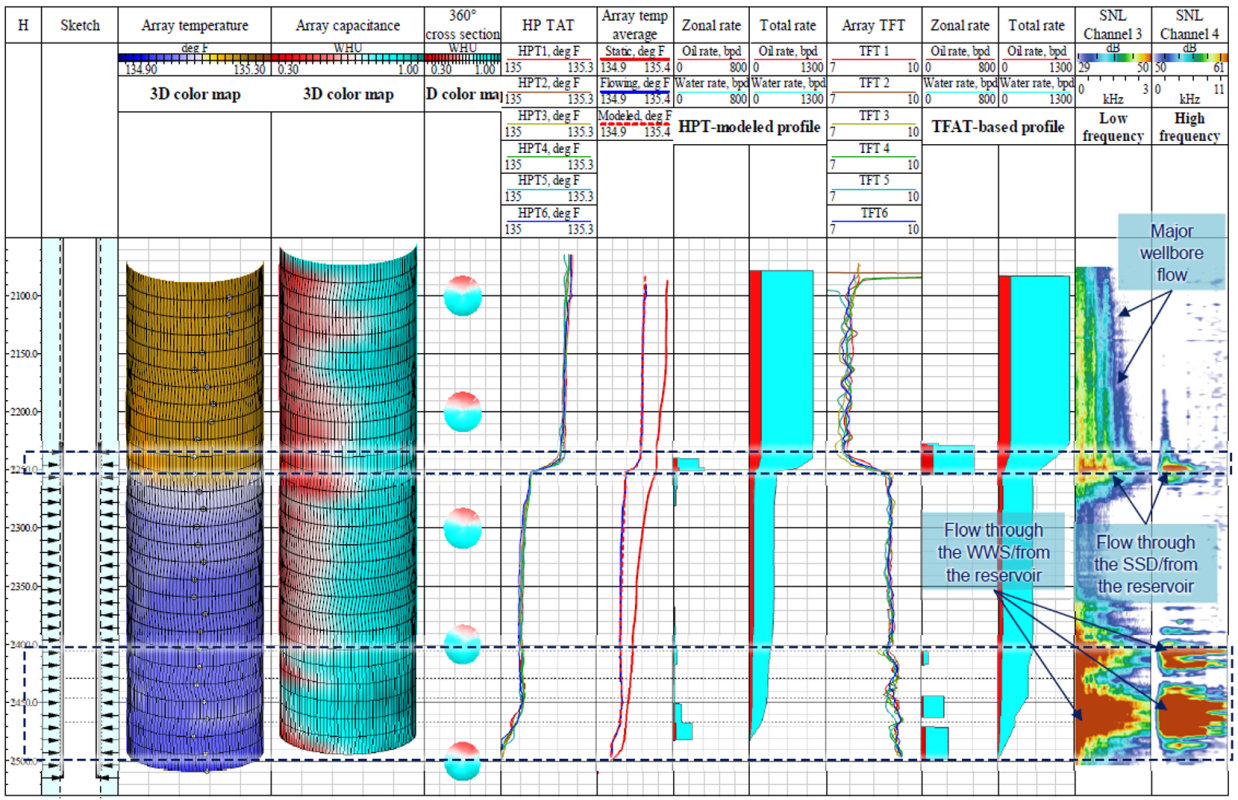

Array Tools Data Analysis

North Side achieves exceptional results by utilizing in-house array logging tools run by skilled logging engineers. Our expert team designs logging programs and processes data, enabling us to maximize well-reservoir potential effectively. We have extensive experience in array Production Logging Tools (PLT) data interpretation including the Spinner Array Tool (SAT), Capacitance & High-Resolution Temperature Array Tool (CAT&HR TAT), Thermal Flow Array Tool (TFAT), and Capacitance & Resistivity Array Tool (CAT & RAT). Swift data processing and timely report generation assist our clients in optimizing survey costs.

Our solutions for Array PLT data analysis assist clients in:

- Reservoir performance evaluation in highly deviated and horizontal wells with segregated flow regimes and tough well & fluid conditions

- Production zones performance detalization

- Frac ports performance evaluation

- EZIPS / Extremal packers integrity evaluation

Data Deliverables

Data deliverables

- 360° evaluation of fluid parameters inside the wellbore

- Detailed production profile addressing the segregation of fluid phases

- Spinnerless evaluation of well-reservoir performance by TFFAT/ T-Flow technologies

Thermal Flow Logging

Analysis

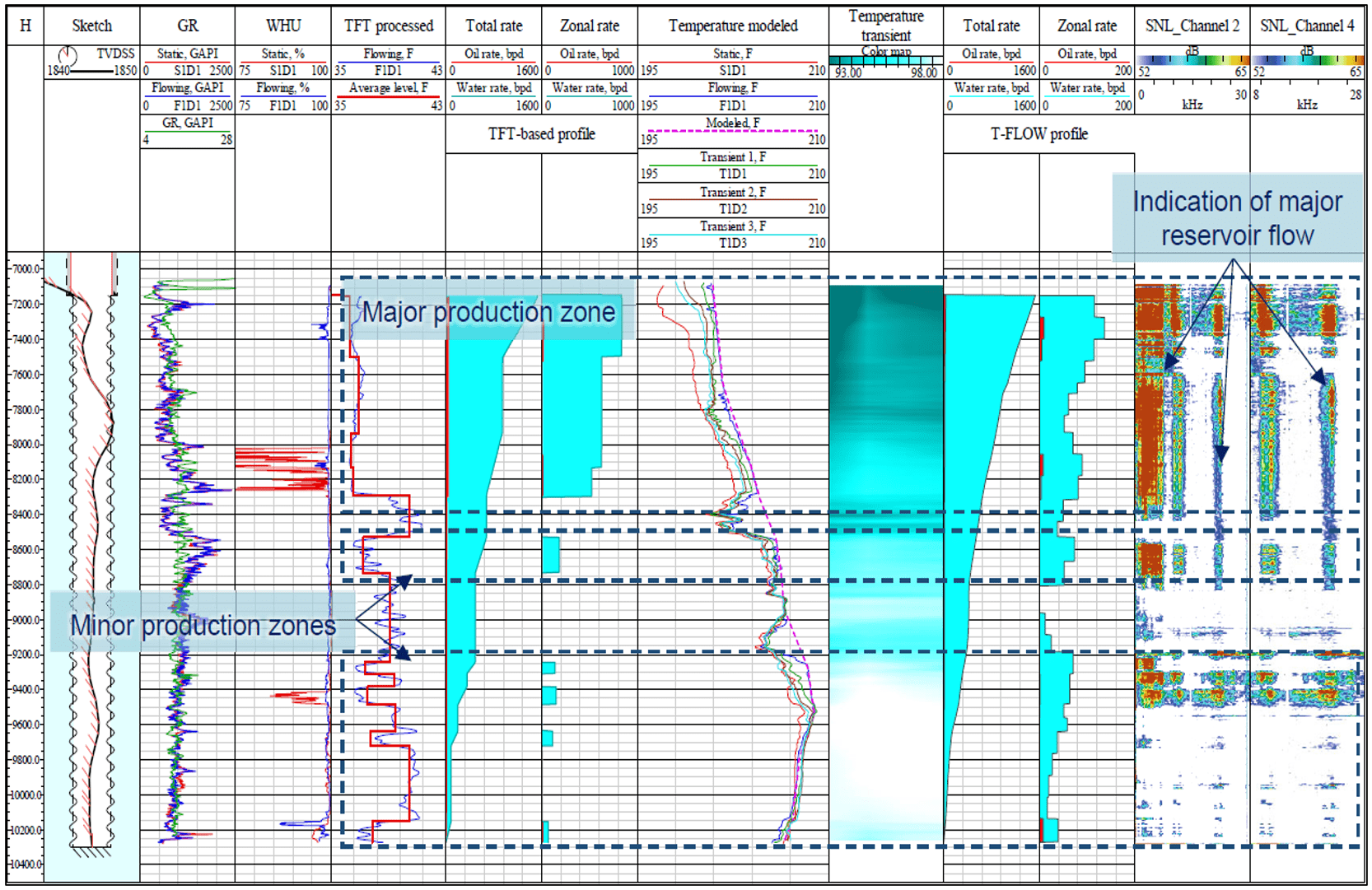

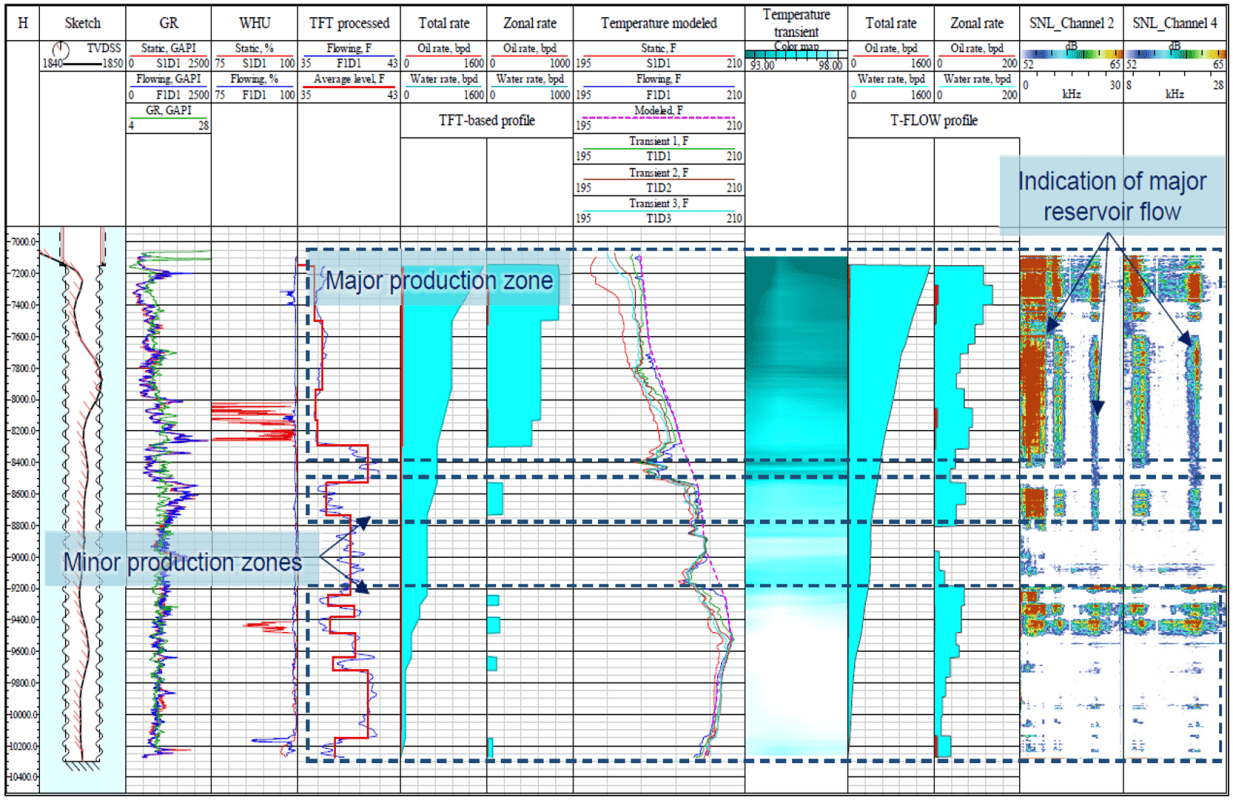

Thermal Flow Logging Data Analysis

The TFT could replace spinners to construct production or injection profiles in such wells where wellbore conditions, trajectory, oil viscosity, or other factors can affect spinner rotation, hence affect data quality. The TFT tool works on the principle of a thermal anemometer: the TFT sensor is heated up by the battery current to a temperature higher than the temperature of the surrounding fluid. The fluid flow cools the sensor and thereby changes its active resistance, which is inversely proportional to the average linear fluid velocity. Based on the recorded data the production/injection profile is calculated.

Our solutions for Thermal flow data analysis assist clients in:

- Qualitative and quantitative analysis of wellbore fluid flow

- Exceptional quality data delivery in tough well-fluid logging conditions where spinner has a limitations

Data Deliverables

Data deliverables

- Detailed wellbore-oriented production/injection profile

- Precise determination of fluid flow zones inside the wellbore in vertical, deviated, and horizontal wells

Reservoir Flow Performance

T-FLOW Profiling

Analysis

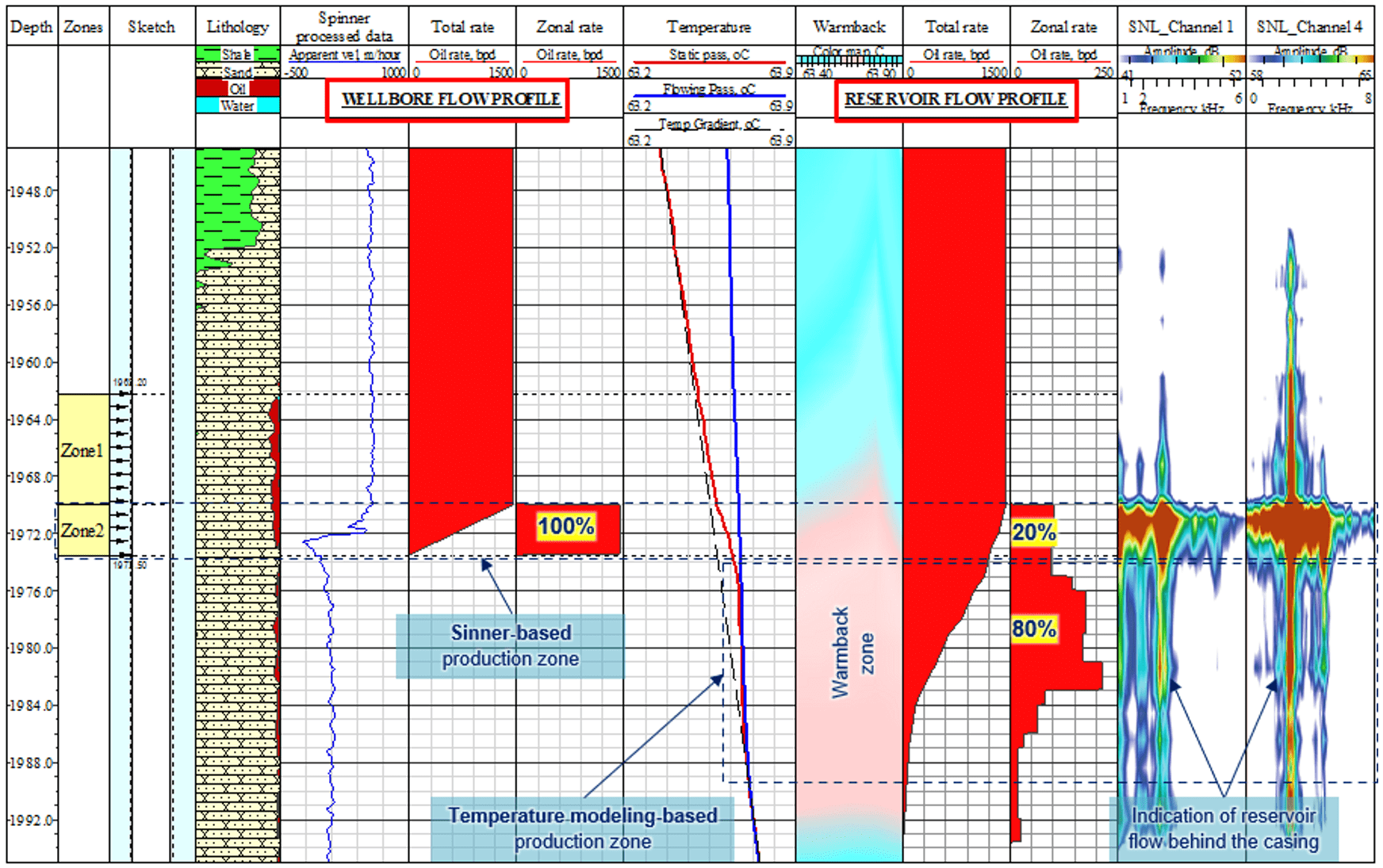

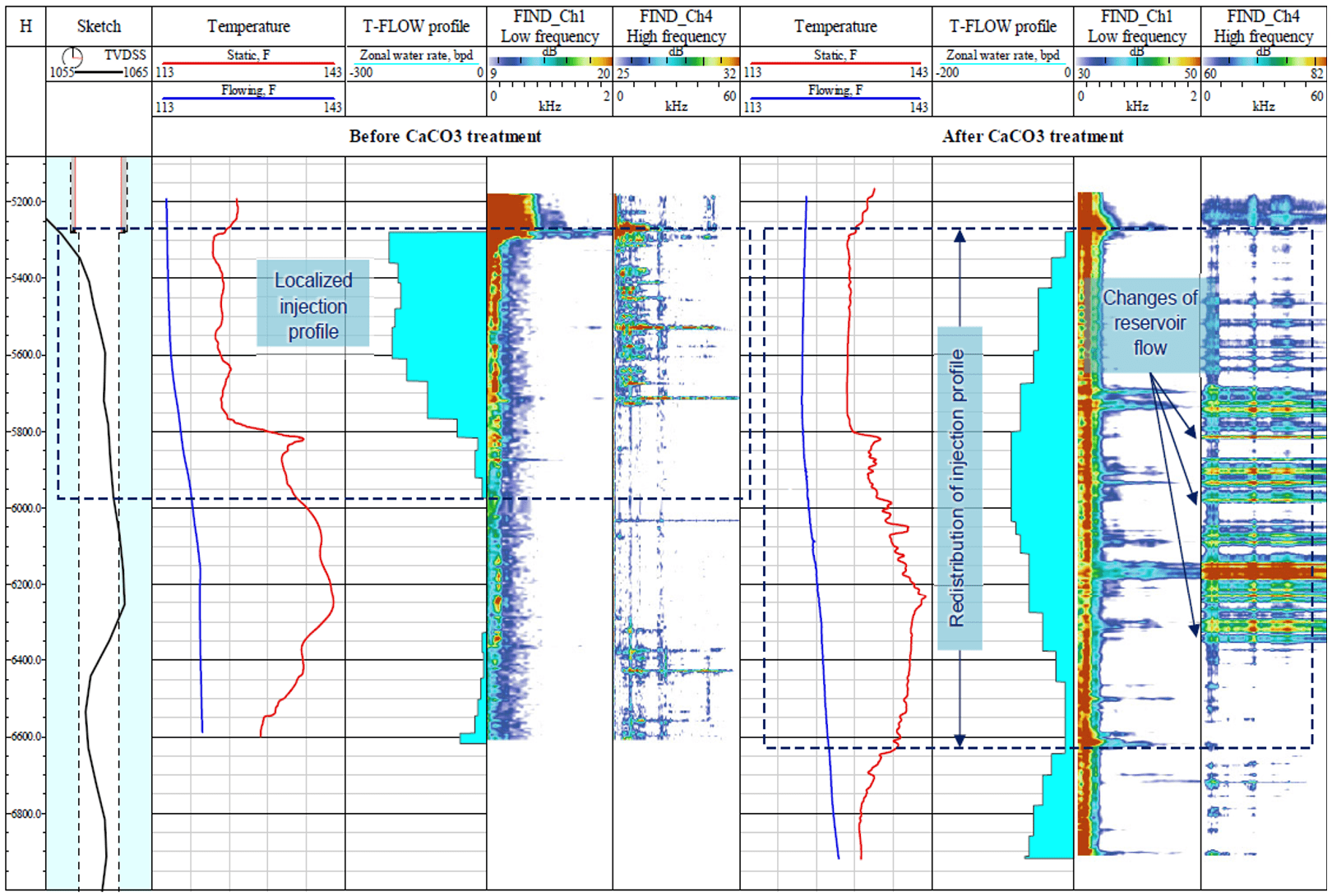

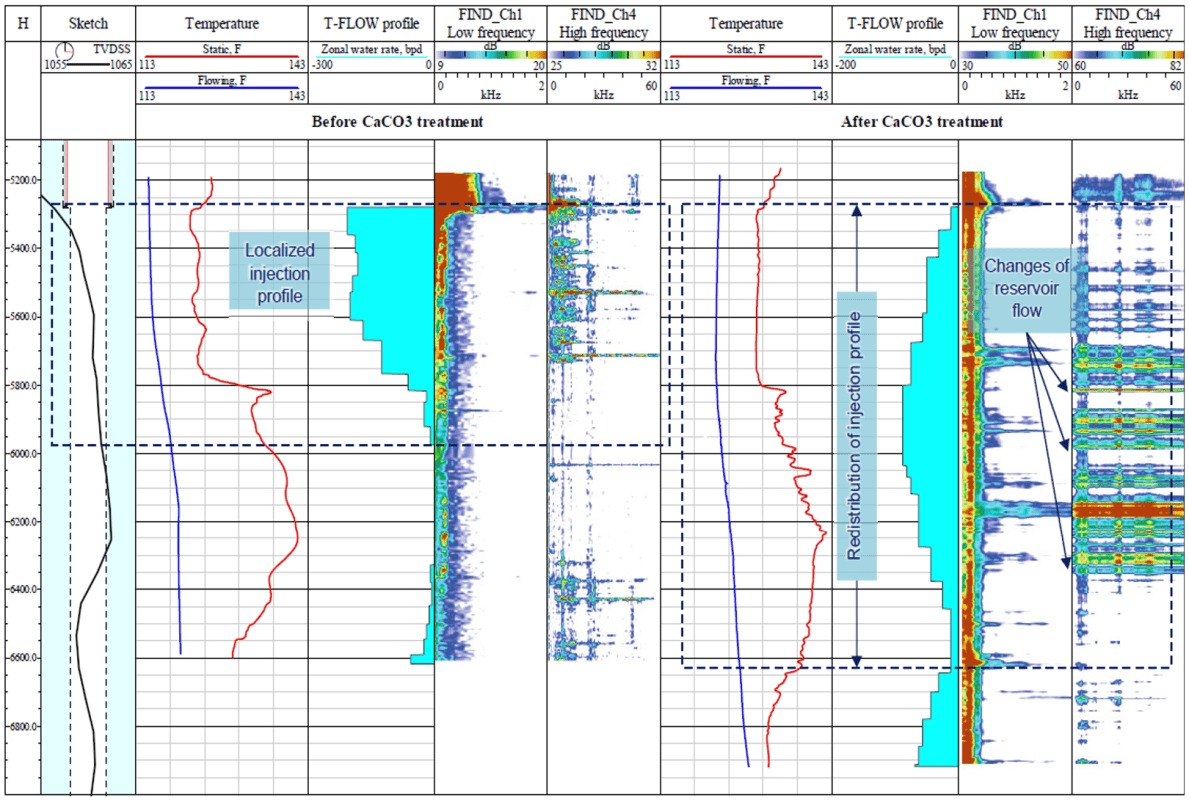

Detailed reservoir flow profiling

T-FLOW is an advanced numerical temperature simulation technology enabling comprehensive evaluation of reservoir flow profile behind the casing and open-hole wells. The technology is based on high-resolution temperature data acquired by the HRT tool from several logging passes conducted in a particular sequence and subsequent processing in in-house software. The math solver allows predicting the heat exchange between the wellbore and the reservoir based on hydro/thermo-dynamic theory.

Our solutions for T-Flow profiling data analysis assist clients in:

- Reservoir performance evaluation

- Qualitative and quantitative analysis of reservoir fluid flow / flow behind casing

- Evaluation of WSO and injection treatment operations efficiency

Data Deliverables

- Detailed reservoir-oriented production/injection profile

- Formation fractures localization

- Flow behind the casing detection

FIND (SNL) Flow Profiling

Analysis

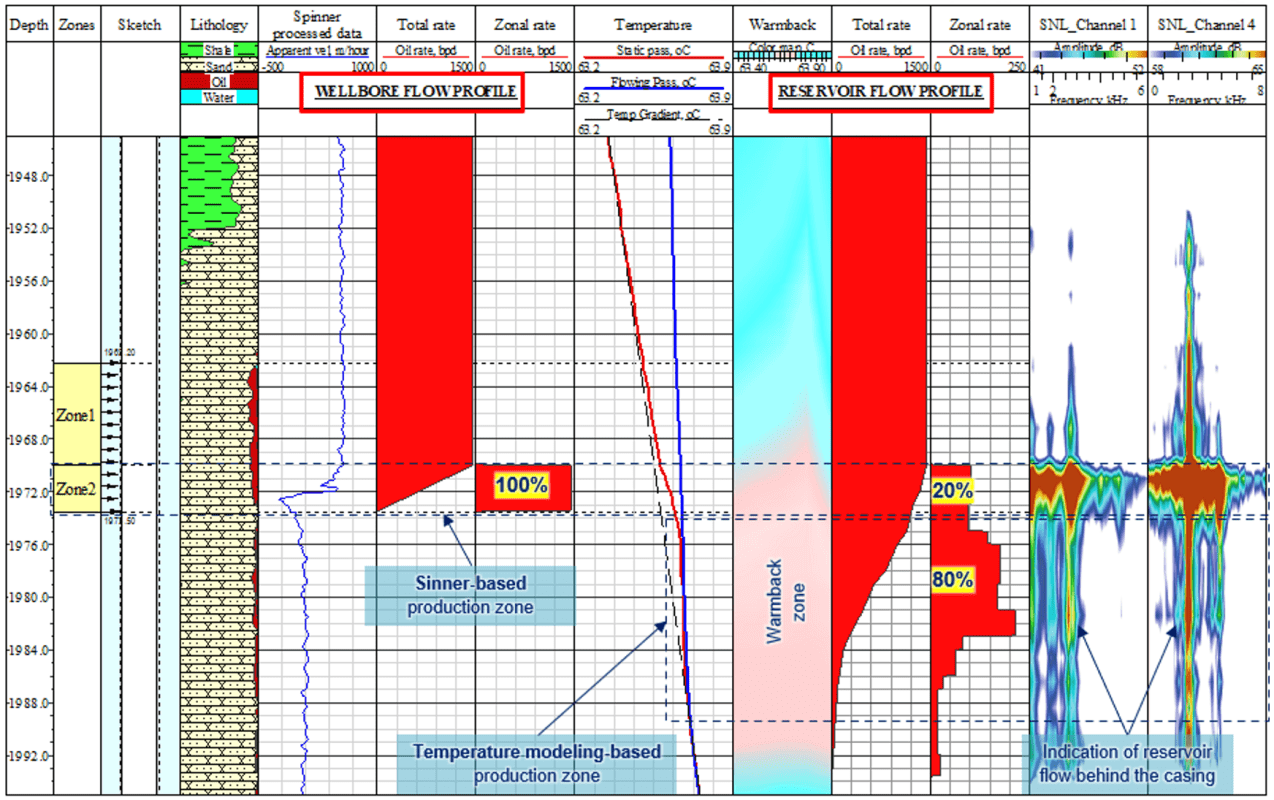

Flow Identifying Noise Detector

The Flow Identifying Noise Detector (FIND) is a new generation of spectral noise logging tool that records data within four independent channels with different frequency ranges and amplification to the signal, which allows the acquisition of the entire noise spectrum data from 0.1 to 60.0 kHz without distortion.

Our solutions for FIND (SNL) data analysis assist clients in:

- Processes behind casing/liner

- Reservoir performance evaluation

- Well integrity evaluation

Data Deliverables

- Detailed reservoir acoustic profile

- Wellbore/ formation flow intervals

- Fractures localization

- Flow behind the casing determination

- Completion elements integrity and functional condition evaluation.

PRODUCTION LOGGING DATA ANALYSIS

Wellbore Flow Profiling

Standard production logging tools are capable of providing a comprehensive well profile, whether it’s related to production or injection activities. In the past decade, North-Side has conducted extensive analysis on hundreds of wells across the globe. We’ve assisted numerous operators in boosting their production rates and have also aided numbers of service companies in delivering top-tier analysis to their clients.

Our solutions for Standard PLT data analysis assist clients in:

- Reservoir performance evaluation

- Identification of cross-flow in multizone perforated wells

- Localization of water source in high water cut wells for further WSO

- Build base-line understanding of well performance after commissioning

Array Tools Data Analysis

North Side achieves exceptional results by utilizing in-house array logging tools run by skilled logging engineers. Our expert team designs logging programs and processes data, enabling us to maximize well-reservoir potential effectively. We have extensive experience in array Production Logging Tools (PLT) data interpretation including the Spinner Array Tool (SAT), Capacitance & High-Resolution Temperature Array Tool (CAT&HR TAT), Thermal Flow Array Tool (TFAT), and Capacitance & Resistivity Array Tool (CAT & RAT). Swift data processing and timely report generation assist our clients in optimizing survey costs.

Our solutions for Array PLT data analysis assist clients in:

- Reservoir performance evaluation in highly deviated and horizontal wells with segregated flow regimes and tough well & fluid conditions

- Production zones performance detalization

- Frac ports performance evaluation

- EZIPS / Extremal packers integrity evaluation

Thermal Flow Logging Data Analysis

The TFT could replace spinners to construct production or injection profiles in such wells where wellbore conditions, trajectory, oil viscosity, or other factors can affect spinner rotation, hence affect data quality. The TFT tool works on the principle of a thermal anemometer: the TFT sensor is heated up by the battery current to a temperature higher than the temperature of the surrounding fluid. The fluid flow cools the sensor and thereby changes its active resistance, which is inversely proportional to the average linear fluid velocity. Based on the recorded data the production/injection profile is calculated.

Our solutions for Thermal flow data analysis assist clients in:

- Qualitative and quantitative analysis of wellbore fluid flow

- Exceptional quality data delivery in tough well-fluid logging conditions where spinner has a limitations

Detailed reservoir flow profiling

T-FLOW is an advanced numerical temperature simulation technology enabling comprehensive evaluation of reservoir flow profile behind the casing and open-hole wells. The technology is based on high-resolution temperature data acquired by the HRT tool from several logging passes conducted in a particular sequence and subsequent processing in in-house software. The math solver allows predicting the heat exchange between the wellbore and the reservoir based on hydro/thermo-dynamic theory.

Our solutions for T-Flow profiling data analysis assist clients in:

- Reservoir performance evaluation

- Qualitative and quantitative analysis of reservoir fluid flow / flow behind casing

- Evaluation of WSO and injection treatment operations efficiency

Flow Identifying Noise Detector

The Flow Identifying Noise Detector (FIND) is a new generation of spectral noise logging tool that records data within four independent channels with different frequency ranges and amplification to the signal, which allows the acquisition of the entire noise spectrum data from 0.1 to 60.0 kHz without distortion.

Our solutions for FIND (SNL) data analysis assist clients in:

- Processes behind casing/liner

- Reservoir performance evaluation

- Well integrity evaluation